Windows as Components|Jean Prouvé’s Windows #5

05 Aug 2025

Even after relinquishing his factory in Nancy, Prouvé did not abandon his philosophy of prefabrication. The fifth installment of “Jean Prouvé’s Windows” focuses on his designs for the windows of the Aluminum Brise Soleil (1964) and Façade Panels Developed for the CCC (1965).

Prouvé’s Prefabricated School Buildings—Part I

Working with the architectural firm Atelier LWD1, which had been designing projects in Africa from 1949 to 1951, Prouvé proposed an experimental prefabricated housing design2 tailored for tropical regions. Its components were to be fabricated at the Maxéville Factory in Nancy, transported by cargo plane, and assembled on site. It was not mass produced, however, as the transportation costs turned out to be much higher than expected, making it more expensive than a conventional locally built home. About 15 years later, in 1964, Prouvé—then a CIMT3 employee—was presented with another opportunity to realize a prefabricated tropical housing design together with Atelier LWD. It came in the form of a competition to build low-cost school buildings with integrated housing in Central Africa (Cameroon), organized by the European Development Fund . This resulted in the LWD-Prouvé team securing a contract to produce 638 building units.

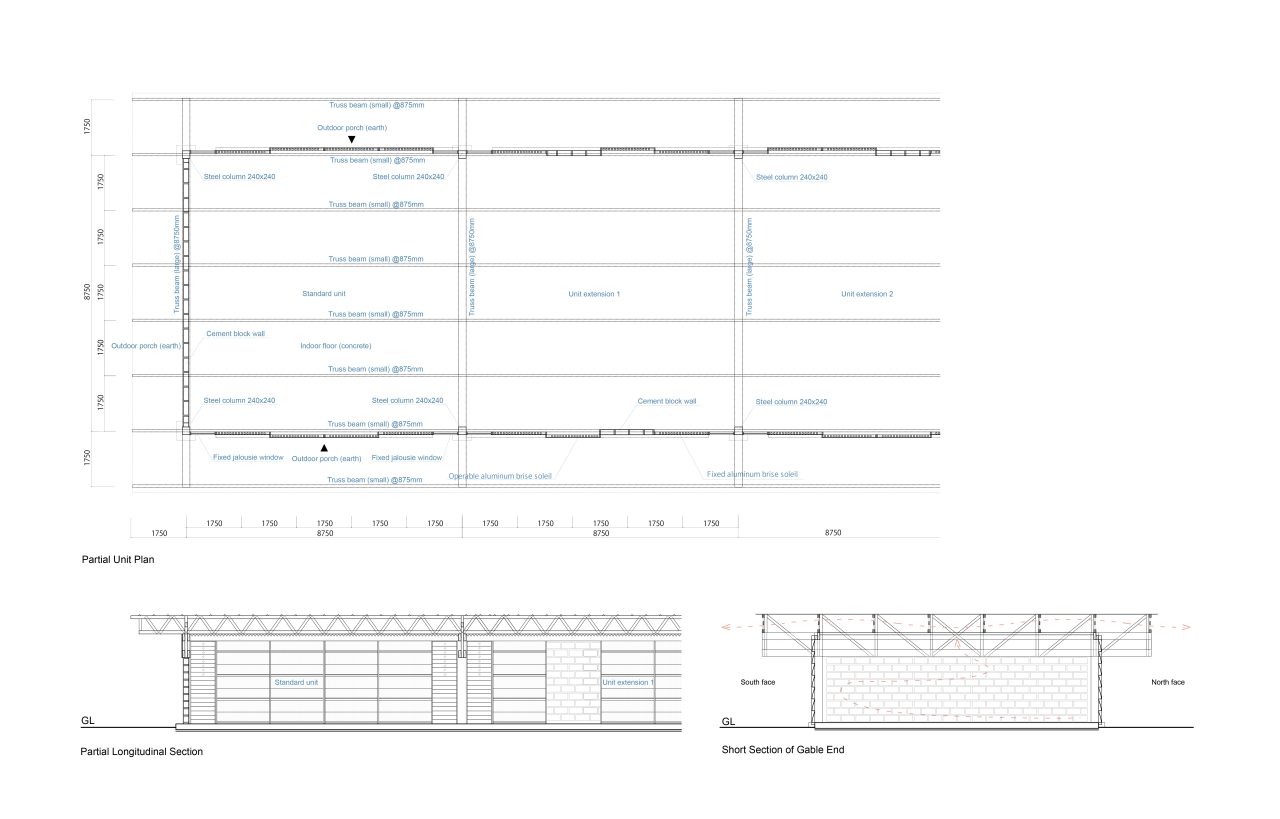

A single building unit measured 8.75 meters by 8.75 meters (76.56 square meters) in plan—or, put differently, it consisted of a 5-by-5 grid of basic square modules measuring 1.75 meters by 1.75 meters, just like the Villejuif Temporary School (1956). The faculty housing, composed of two linked units (153.12 square meters), and the classroom buildings, ranging from one to six linked units (76.56 to 459.37 square meters), were proposed as rectangular buildings that could be expanded indefinitely in one direction. The slight difference between this prefabricated design and earlier ones was that it was explicitly intended to incorporate many components that could be fabricated from locally available materials and easily assembled by local laborers, such as concrete floors, cement block walls, and wooden truss beams.

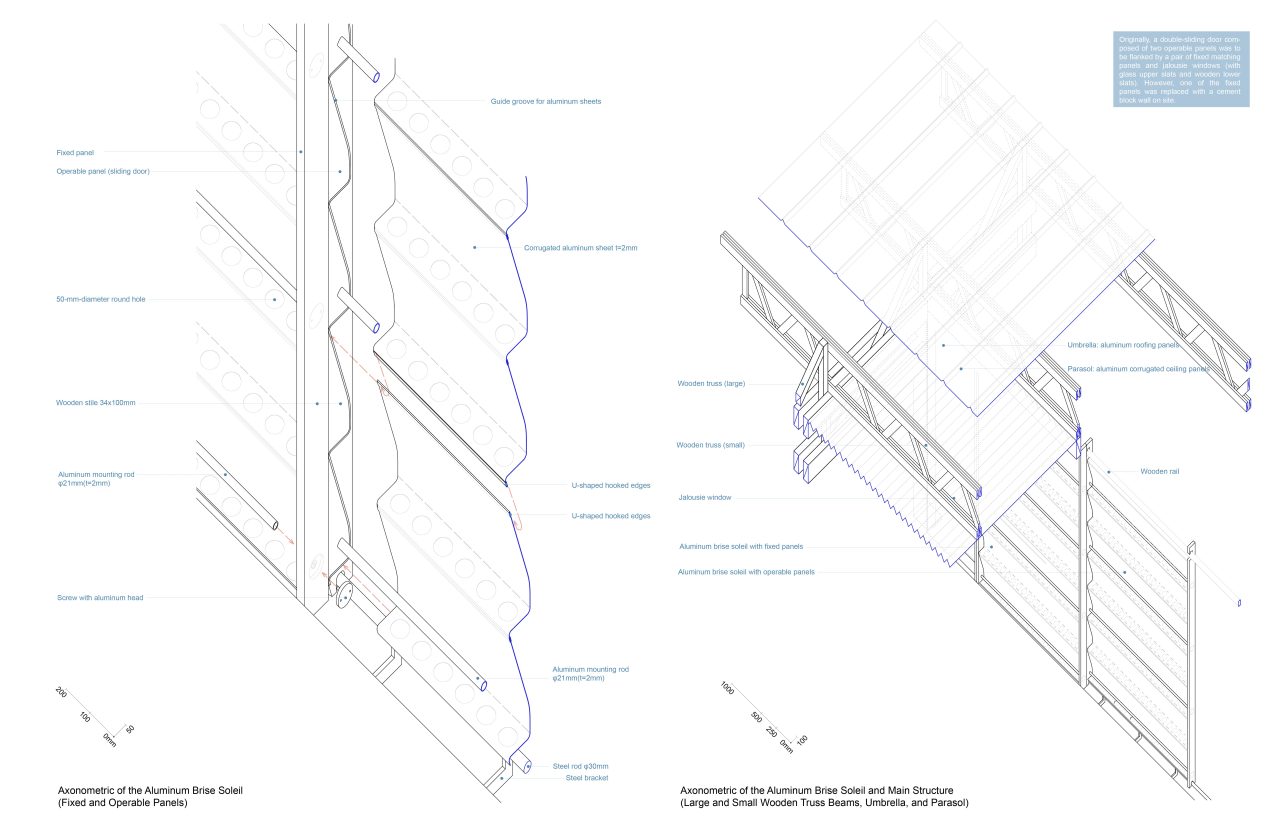

Assembly entailed setting French-made steel columns at the four corners, connecting each column pair with a large locally fabricated wooden truss beam, and spanning eight smaller wooden truss beams across the top of the large truss beams to bind the latticed framework together. The wooden truss beams (both large and small) were cantilevered beyond the envelope to form eaves, whose lengths were calibrated to the angle of the sun to shield the interior from direct sunlight. The main structure was completed with the addition of aluminum roofing trays and aluminum corrugated ceiling panels, which were laid out above and suspended beneath the smaller truss beams, respectively. Referred to as the “umbrella” and “parasol”, these aluminum roof and ceiling elements formed part of the environmental system for regulating heat gain. The units’ gable ends (short sides of the buildings) were either closed off with cement block walls or connected to other units. In contrast, the front and back faces (long sides of the buildings) were designed with openings, which were fitted with Prouvé’s Aluminum Brise Soleil (Fr. Brise-soleil, Cameroun).

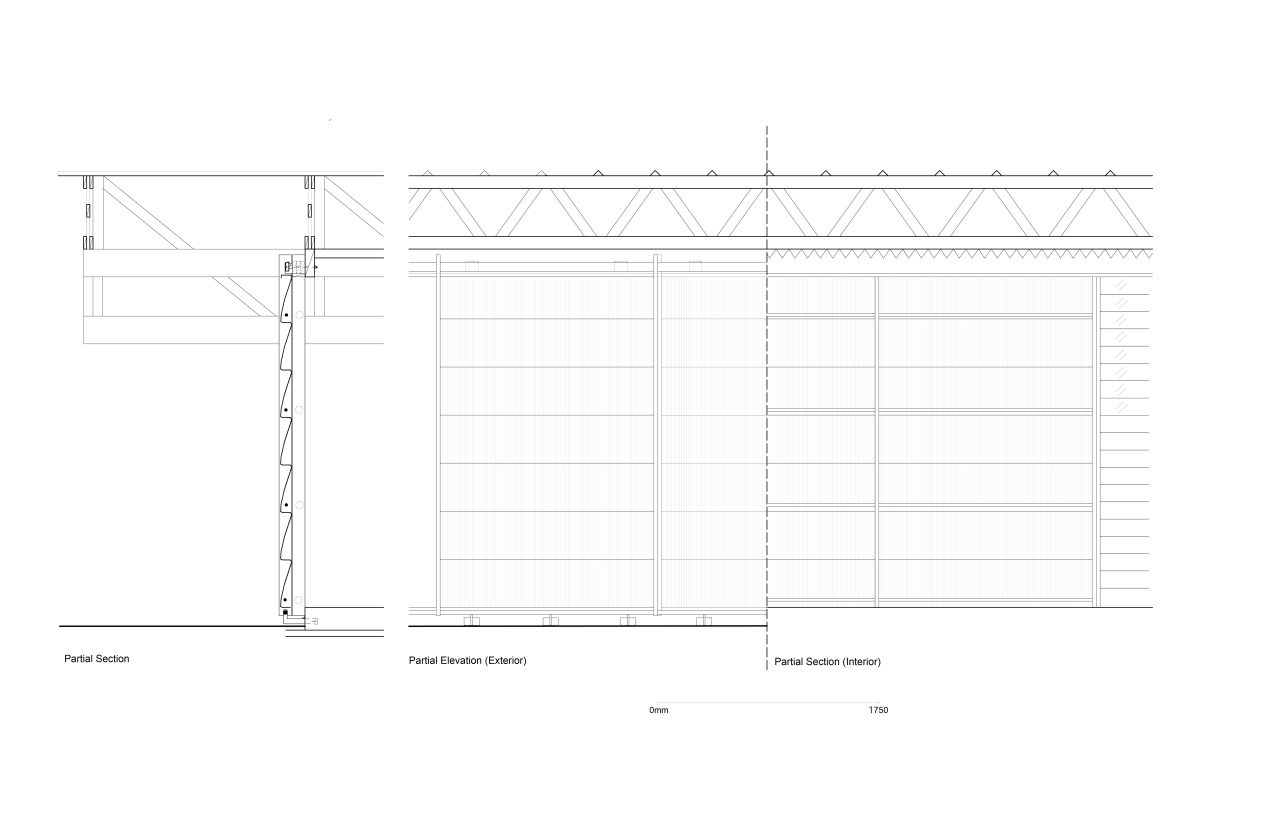

Tropically Adapted Undulating Façades with Small Round Windows

The Aluminum Brise Soleil, installed along the buildings’ front and back—or north and south—façades (long sides), was a component that was flown in from France and assembled on site. Measuring approximately 2.8 meters in height and 1.75 meters in width when assembled, they consisted of seven 2-millimeter-thick folded corrugated aluminum sheets, two wooden stiles (34 millimeters wide and 100 millimeters deep), and four aluminum mounting rods (21 millimeters wide and 2 millimeters thick). They were assembled simply by hooking together the U-shaped top and bottom edges of the corrugated aluminum sheets and inserting them into guide grooves cut into the wooden stiles. As there were no top and bottom rails connecting the stiles, the aluminum mounting rods provided in-plane rigidity. The most distinctive feature of the design was the series of eighteen 50-millimeter-wide round holes that were spaced 90 millimeters apart along the horizontal ledges at the lower part of each corrugated aluminum sheet. These holes, which were left unglazed because the vertical sections of the sheets had just the right curvature to prevent rainwater penetration, could be described as small windows that drew in both fresh air and indirect light reflected off the curved surfaces.

-

© Galerie 54 – Eric Touchaleaume, Paris.

There were both fixed and operable versions of the Aluminum Brise Soleil, though both were composed of the same elements. The operable versions functioned as sliding doors simply by means of keyhole-shaped notches cut into the top and bottom ends of their stiles. These sliding panels hung from a wooden rail and sat on a steel rod (30 millimeters wide), which was supported by steel brackets projecting from the concrete floor slab and served as a door runner. While giving the front and back façades (long sides) the appearance of impervious, undulating surfaces from a distance, the design of the extremely constricted round windows traded off direct ventilation and views for enhanced cross-breezes through the gap between the umbrella and parasol by harnessing the roughly 10-degree-Celsius temperature difference between day and night. The window design was thus adapted to the tropical climate, forming part of the environmental control system for drawing hot air out from below the ceiling.

Prouvé’s Prefabricated School Buildings—Part II

In 1962, the French Ministry of Education organized a design-build competition (Fr. Concours Conception-Construction, CCC). The competition called for submissions from joint ventures—that is, teams of architects and contractors—as is quite common nowadays, making it an ideal opportunity for Prouvé, whose employer, CIMT, already possessed the facilities needed for prefabricated production. The brief asked for design and construction plans for new schools with a 600-student capacity in several regions, including not only classroom buildings but also associated facilities such as dormitories for 160 residents, gymnasia, and auditoria. Out of the 186 teams that participated in the competition, 72—including Prouvé’s—remained as finalists after two rounds of evaluation. Ultimately, Prouvé’s team built seven schools4 of varying size across France.

-

© ADAGP, Paris & JASPAR, Tokyo, 2025 E5977

Like the Villejuif Temporary School, the classroom building design proposed by Prouvé’s team had a rectangular plan configured on a 1.75-meter-square grid. Its short side had a fixed dimension of 17.5 meters (10 grid squares), while the long side was infinitely extendable. A hallway with a width of 3.5 meters (2 grid squares) ran down the middle and was double-loaded with various rooms, each 7 meters wide (4 grid squares). The design allowed the floors to be laid out using a mix of five differently sized spaces (modules), which included a large classroom (4×6 grid squares, or 73.5 square meters), a medium classroom (4×5 grid squares, or 61.25 square meters), a small classroom (4×3 grid squares, or 36.75 square meters), an entrance hall, a stairwell, a faculty room (4×2 grid squares, or 24.5 square meters), and restrooms (4×1 grid squares, or 12.25 square meters). The main structural framework was built of reinforced precast concrete (PCa) components fabricated on site, while the envelope was composed entirely of curtain wall components produced in a factory.

-

© Centre Pompidou, MNAM-CCI Bibliothèque Kandinsky, Dist. GrandPalaisRmn / Fonds Prouvé / distributed by AMF

-

© Centre Pompidou, MNAM-CCI Bibliothèque Kandinsky, Dist. GrandPalaisRmn / Fonds Prouvé / distributed by AMF

To assemble, H-shaped axial portal frames (Fr. portique axial en H)5—precast reinforced concrete structural elements that combined a pair of columns with a crossbeam—were placed every 3.5 meters (one per two 1.75-meter bays) along the building’s longitudinal axis and linked together with rectangular PCa beams. Next, U-shaped PCa perimeter columns, which doubled as mullions, were placed at 1.75-meter intervals along both sides of this central spine, to which they were joined with U-shaped PCa beams, also spaced at 1.75 meters. The reduced distance between the support points eliminated the need for secondary longitudinal bracing beams and also enabled the reinforced PCa slabs to be just 60 millimeters thick. The assembly could be stacked up to five stories, each with a unified height of approximately 3.3 meters. The choice of a PCa structure was based on the facts that it provided the acoustic insulation required as a basic necessity for a school, could be constructed more quickly than a steel structure, could be flexibly deployed in various regions, and reduced transportation costs. True to intention, the design enabled two spans of a single story to be fabricated and assembled per day.

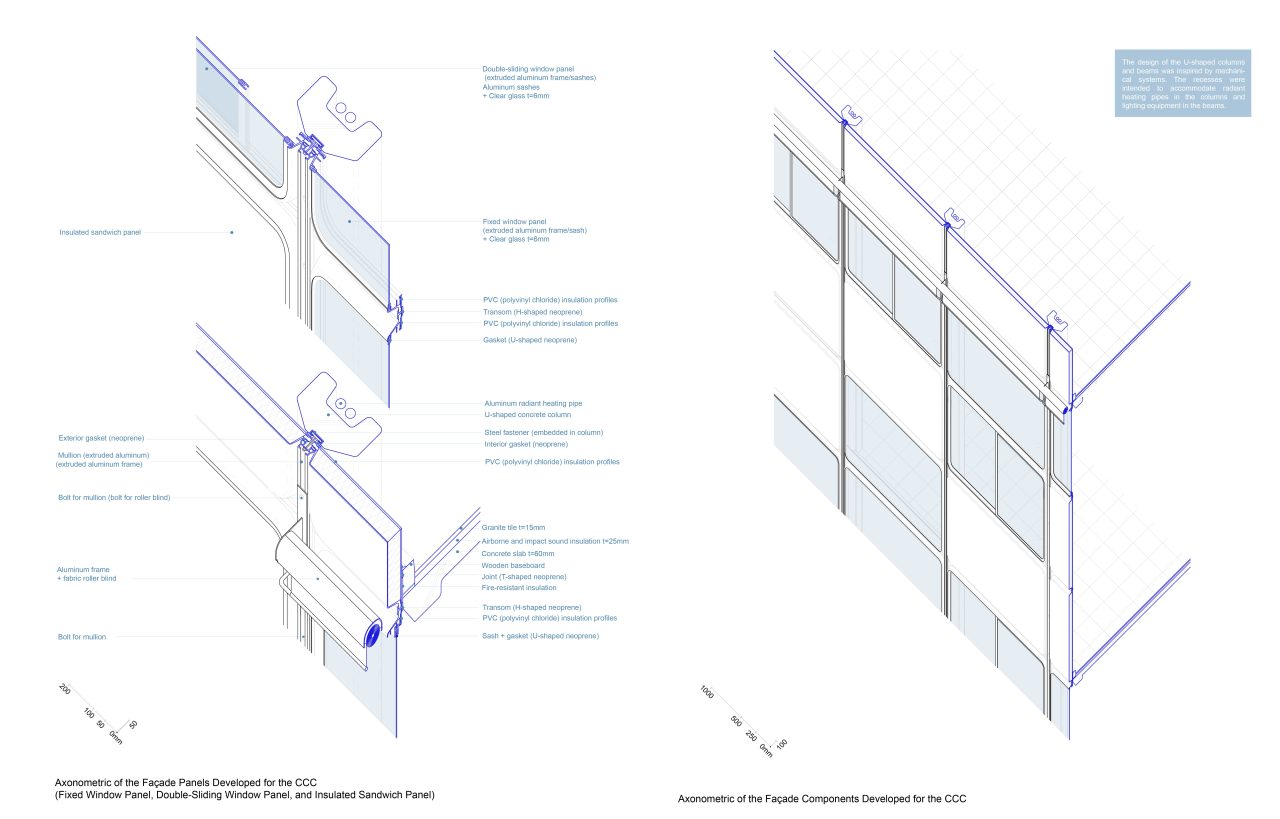

A Three-Type Window Panel System

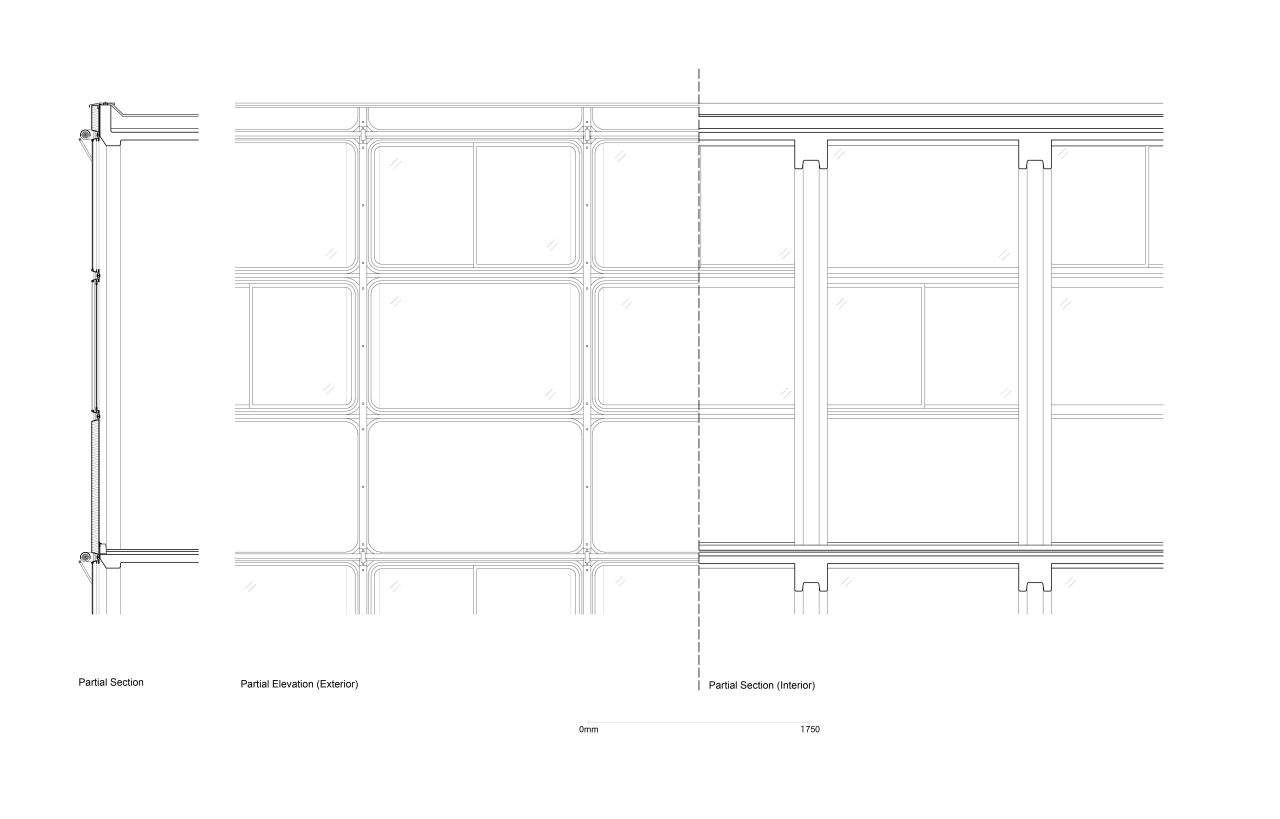

While the classroom building presented solid-wall façades made of concrete components fabricated on site at its short sides (gable ends), its long sides (front and back faces) were fitted with characteristically Prouvéan prefabricated curtain wall panels: the Façade Panels Developed for the CCC (1965) (Fr. Panneaux de façade développés pour C.C.C.).

There were three types of these façade components: fixed window panels for daylighting, double-sliding window panels for daylighting and ventilation, and solid sandwich panels for thermal insulation and visual privacy. All had a unified width of 1,750 millimeters, which matched the dimension of the plan’s grid. They also had a unified height of 1,100 millimeters, such that any combination of three stacked panels aligned with the height of a story. The double-sliding window panels were composed with an extruded aluminum frame simply fitted with glazed aluminum sashes, as is commonly done today. On the interior side, the openings’ edges were sealed using PVC (polyvinyl chloride) insulation profiles to mitigate heat bridging. The fixed-glass window panels made use of the same extruded aluminum frames as the double-sliding window panels in typical Prouvé fashion. The insulated sandwich panels, in contrast, were composed of press-formed steel plates with a powder-coated paint finish, and they were made in five color variations. All three panel types were tapered in the same way along their outer edges, and they shared the same mullion and transom details.

-

© Centre Pompidou, MNAM-CCI Bibliothèque Kandinsky, Dist. GrandPalaisRmn / Fonds Prouvé / distributed by AMF

-

© Centre Pompidou, MNAM-CCI Bibliothèque Kandinsky, Dist. GrandPalaisRmn / Fonds Prouvé / distributed by AMF

To install the panels to the building structure, which supported their weight, their side edges were externally bolted to a steel fastener embedded in the face of each U-shaped concrete column-mullion, together with a vertical joint profile (extruded aluminum) and interior and exterior gasketing. As this detail took care of supporting the panels, the connections between vertically adjacent panels were made simply by inserting the panels’ top and bottom edges into grooves in the transoms (H-shaped neoprene), regardless of panel type. This window panel system enabled one to create homogeneous façades by using a single type of panel or a countless variety of unique, rhythmically articulated façades by combining the two types of window panels and five types of colored sandwich panels as appropriate to the functions of the interior spaces. It was a quintessentially Prouvé design that transformed simple elements in diverse ways.

Prouvé’s Third Chapter

Rewind to 1956. After establishing Jean Prouvé Constructions with Michel Bataille and completing the Villejuif Temporary School that year, Prouvé was struggling to secure adequate remuneration for the project and was also about to see his plans to build a new factory for mass-producing the Maison des Jours Meilleurs (1956)6 with CIMT’s backing fall through. Around the time when the Cachat Buvette in Évian opened its doors in May 1957, both Jean Prouvé Constructions and Société Goumy folded and were acquired by CIMT. It had only been a year since Prouvé had set up his company. For roughly the next decade, from 1957 to 1966, he worked as a consultant engineer in CIMT’s construction division branch, run out of Société Goumy’s former office, while maintaining his freedom through freelancing. The number of window designs integrated with the structure rapidly dwindled from Prouvé’s architectural projects during this time, as he shifted to designing windows only as part of prefabricated curtainwall systems—or, in other words, windows designed purely as components, as illustrated by the Aluminum Brise Soleil and Façade Panels Developed for the CCC.

Notes

1: Atelier LWD was an architectural firm founded by Guy Lagneau, Michel Weill, and Jean Dimitrijevic. Shortly after its founding, the firm relocated from France to Africa, where it carried out the bulk of its design work. It collaborated with Prouvé beginning with its first commission in Africa, the Hotel de France in Conakry (1953).

2: The Maison Tropicale (1949–1951) was an experimental house Prouvé developed for the West African climate by modifying an earlier housing design composed of steel axial portal frames and aluminum façade panels with built-in round windows. Only two were built: one in Niamey, Niger, and the other in Brazzaville, Congo. The house was horizontally penetrated by a distinctive ridge vent, created by adding an eye-shaped opening at the top of each portal frame. By generating a chimney effect, the vent served to draw air out from the interior. Designed with consideration for sunlight, rain, wind, and daily temperature fluctuations, the house also featured a wraparound veranda equipped with modular 2-meter-wide brise soleil (sunshades) made of aluminum sheets. The angles of the brise soleil fins could be adjusted by hand.

3: “CIMT” is an acronym for Compagnie Industrielle du Matériel de Transport. At the time, the company had been developing and manufacturing Paris’s subway cars. It began collaborating with Prouvé as it looked to expand into the construction sector, having developed a close relationship with the architect after becoming the exclusive manufacturer of the steel building system cores of the Maison des Jours Meilleurs.

4: Based primarily on documents for the Saint-Étienne (Isère) Junior Secondary School (Fr. Saint-Étienne (Isère) collège d’enseignement secondaire), which was designed collaboratively by Prouvé and Léon Petroff of CIMT and the architects Joseph Belmont, Jean-Claude Perillier, and Maurice Silvy. The following is a list of schools so far confirmed to have been designed by Prouvé.

1. Barnave Middle School (Fr. Collège Barnave) (Saint-Égrève, 1965)

Some of the structural elements have been reused, and the façades have been renovated. Some original façade panels remain intact on the gymnasium.

2. Bressuire Junior Secondary School (Fr. Bressuire collège d’enseignement secondaire) (Bressuire, 1965)

Some of the structural elements have been reused, and the façades have been renovated.

3. Faverges Middle School (Fr. Collège Faverges) (Faverges, 1965)

No longer exists.

4. Léonce-Vieljeux Middle School (Fr. Collège Léonce-Vieljeux) (Les Vans, 1965)

No longer exists.

5. Parmentier Middle School (Fr. Collège Parmentier) (Montdidier, 1965)

No longer exists.

6. Jean-Bart High School, André-Argouges School Complex (Fr. Lycée Jean-Bart, cité scolaire André-Argouges) (Grenoble, 1966)

Some of the structural elements have been reused, and the façades have been renovated.

7. Jean-Jacques Rousseau High School (Lycée Jean-Jacques Rousseau) (Sarcelles, 1965)

Some of the structural elements have been reused, and the façades have been renovated. The entrance gate, constructed by repurposing the reinforced concrete H-shaped axial portal frames and thin slab, remains intact.

5: The H-shaped axial portal frame is one of nine types of structures presented in the “Alphabet of Structures” chart in the 1971 publication Jean Prouvé: Prefabrication, Structures and Elements. The chart also includes the béquille used at the Villejuif Temporary School and Cachat Buvette in Évian.

6: In the winter of 1954, a woman died of exposure on a Parisan street during sub-zero temperatures. Saddened by the incident, the Catholic priest Abbé Pierre launched a fundraising campaign in an effort to provide housing for the poor. The goal of the “Les Jours Meilleurs” (“For Better Days”) campaign was to construct 200 homes funded through donations and coupons attached to products sold by the detergent manufacturer Persil. Prouvé was asked to design a prototype for the project in January 1956, and on February 20—just 30 days later—he demonstrated the construction of the prototype, named the Maison des Jours Meilleurs, at an event held on a bank of the Seine. The event attracted not only many spectators but also numerous unsolicited helpers, causing the construction process to take much longer than the planned seven hours. Nevertheless, it generated great public interest, and Persil received one million coupons the following day. In plan, the building consisted of two bedrooms, a living room directly accessible from the front entrance, a dining area, and a kitchen served by a rear entrance. Positioned at the center of the house was the monobloc: a factory-made metallic core—or, what might be described as a prefabricated building system core with an integrated bath and kitchen—that also served as the primary structure supporting the roof. The envelope was formed by modular wooden panels set atop the raised rim of the concrete floor slab. Although several additional homes were built in the six months following the prototype’s completion, the central placement of the building system core in the living room proved too avant-garde for its time, and the project was discontinued after French authorities refused to approve further construction. It was through this project that Prouvé began his relationship with CIMT, which handled the production of the monoblocs.

References

Peter Sulzer, Jean Prouvé: Complete Works: Volume 4: 1954–1984 (Basel: Birkhäuser, 2008), 180–181, 186–191, 300.

“Saint-Égrève (Isère): Collège d’Enseignement Secondaire”, Techniques & Architecture, 26 (1965): 147–152.

Bruno Reichlin, et. al., Jean Prouvé: The Poetics of Technical Objects (Tokyo: TOTO, 2004).

Jean Prouvé, Kochiku no Hito: Jean Prouvé (Jean Prouvé par lui-même), trans. Reiko Hayama (Tokyo: Misuzu Shobo, 2020).

https://www.jeanprouve.com

https://galerie54.com/en/jean-prouve-architecture

Top image: © Galerie 54 – Eric Touchaleaume, Paris.

Shin Yokoo

Founded Ouvi in 2004 after completing a masterʼs degree in architecture at the Tokai University Graduate School of Engineering and working at the Masahiro Ikeda Architecture Studio. Earned a PhD (Engineering) from the Tokyo University of Science Graduate School of Science and Technology in 2016. Special lecturer at the University of Belgrade from 2017 to 2019 (one-year trainee of the Agency for Cultural Affairsʼ overseas study program). Visiting senior fellow at the National University of Singapore since 2020, Senior Lecturer from 2022. Visiting associate professor at the Tokyo University of Science from 2022. Notable works include the Matsumoto Sannomaru Square (2023; designed by Tatsuo Iwaoka Laboratory + MORIIS ATELIER), the MNH (2023; designed by ICU), the House in Nakago (2021; collaboration with Snark), 4 Episodes (2014; Atelier Nishikata), and Jukkaie (2009; collaboration with Point). Notable research includes “Design Feature of ʻMaison du Peuple de Clichyʼ Designed by E. Beaudouin, M. Lods, J. Prouvé”, (AIJ Journal of Technology and Design, Jun. 2015), “Study on the Relationship Between Features and Building Components of ʻAéro-Club Roland-Garros à Bucʼ” (AIJ Journal of Architecture and Planning, Jun. 2015), and “Study on the Relationship between Features and Building Components of ʻMaison démontable en ancier BLPSʼ” (AIJ Journal of Architecture and Planning, Sep. 2017), among others.